CHIDORI®

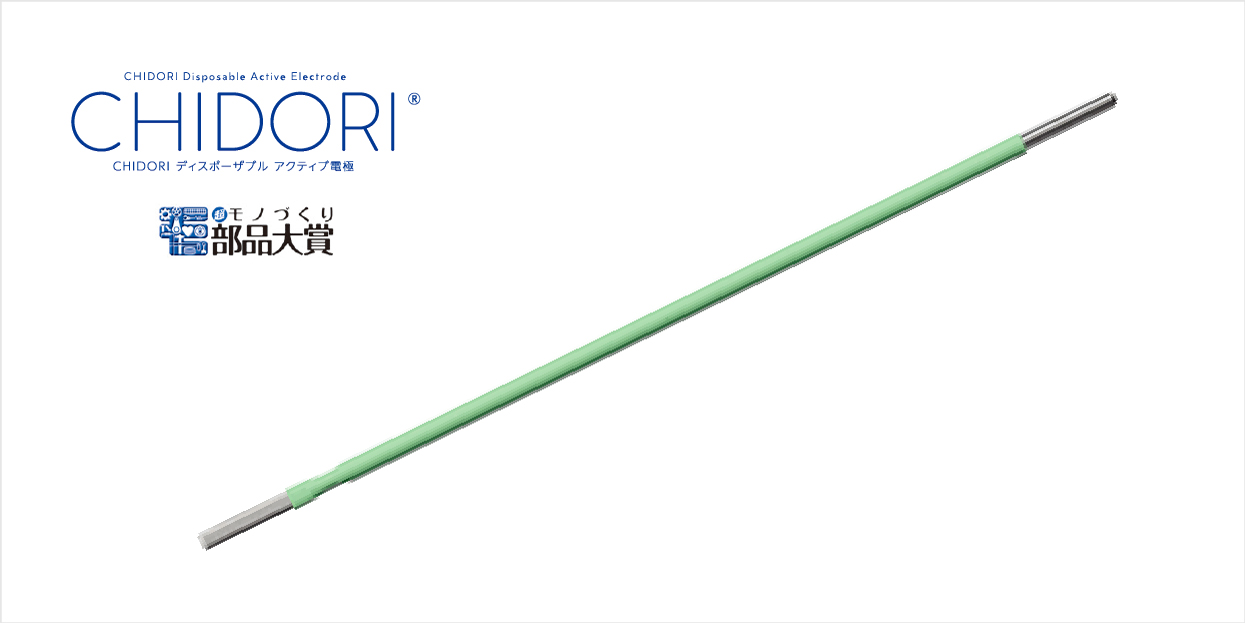

CHIDORI® Disposable Active Electrode

CHIDORI, the fist medical device produced by the Medical Device Group, was created with our desire to utilize Nihon Parkerizing’s surface treatment technology to reduce the burdens on patients and medical providers.

Going forward, we hope to establish a sales network to enable this product to be used by people worldwide, not only within Japan. In addition, we will continue to strive to create and manufacture, so that the Medical Device Group’s products can serve useful functions for both patients and medical providers.

Product Features

An electrosurgical knife is a tool with a high-frequency electric current applied to the metal blade, used to make incisions and to arrest bleeding in the human body.

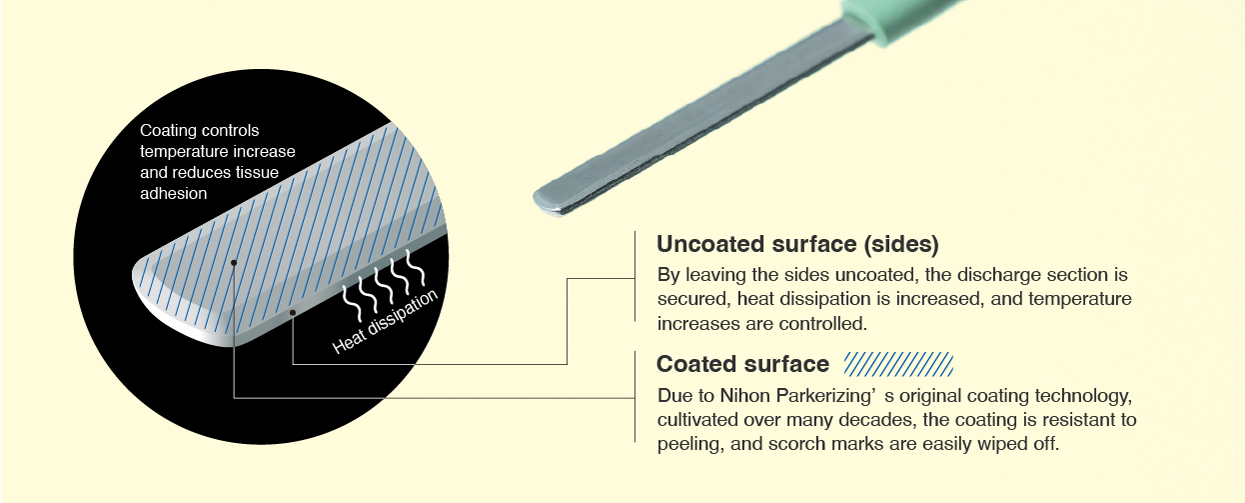

Utilizing Nihon Parkerizing’s original metal surface treatment technology, we apply a coating of a newly-developed surface treatment agent to specific areas of the blade tip (active electrode) of an electrosurgical knife, resulting in the new added functions of the ability to suppress carbide adhesion, and to control temperature increase.

-

- Tissue adhesion is reduced by Nihon Parkerizing’s silicon coating.

- Temperature increase is controlled by leaving the sides uncoated.

- Entire process is handled within Japan, from product pressing to sterilization.

- Optimized coating for active electrodes, using Nihon Parkerizing’s coating agents.

- Leaving only the sides uncoated, using coating technology developed in automotive parts production, controls temperature increases and maintains blade sharpness.

Technological Innovation

At Nihon Parkerizing, we developed a surface treatment agent that enables the suppression of carbide adhesion. In addition, we intentionally exposed the edges of the scalpel tip electrode in order to control rises in temperature by increasing the resistance value. In specific terms, since carbide adhesion occurs at the widest area, which is the flat section of the scalpel tip electrode, we apply a coating to this section using a silicone resin-type surface treatment agent developed by Nihon Parkerizing, resulting in the suppression of carbide adhesion. Furthermore, we achieved the ability to control rises in temperature by increasing the resistance value through leaving only the side sections of the blade uncoated, using a coating technique that enables minute variations in coating coverage.

Performance Test Results

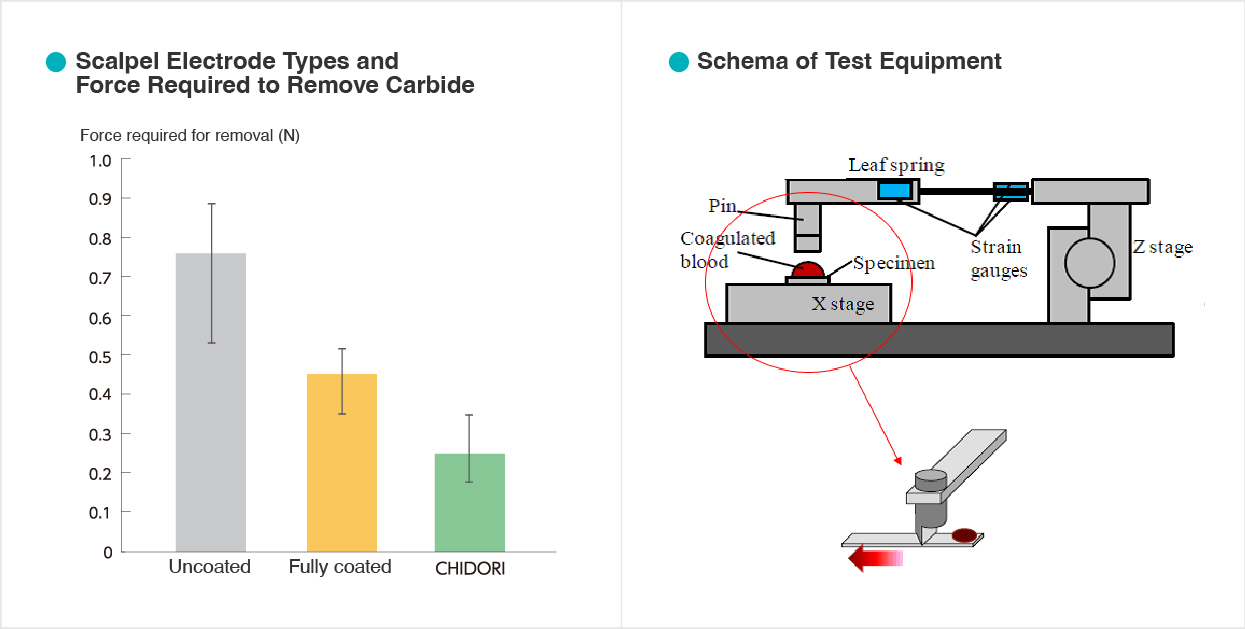

Suppression of Carbide Adhesion

Evaluation was conducted using a scratch tester to measure the adhesion strength of blood carbide. Since coagulated blood that adheres to the scalpel tip electrode during real-life surgical procedures is removed by scraping with a file or other tool, the scratch tester serves as a simulation of these conditions. The tested units were an uncoated scalpel electrode, a fully coated scalpel electrode, and CHIDORI. The tips of the three units were inserted in 2mm of porcine blood and discharged, causing scorching on the surface of the scalpel tip electrode. The amount of force required to remove the scorched blood was measured, with the following results. The uncoated unit required the highest amount of force, at approximately 0.76N, and the fully coated unit required approximately 0.45N. In comparison, CHIDORI required the lowest amount of force, at approximately 0.25N.

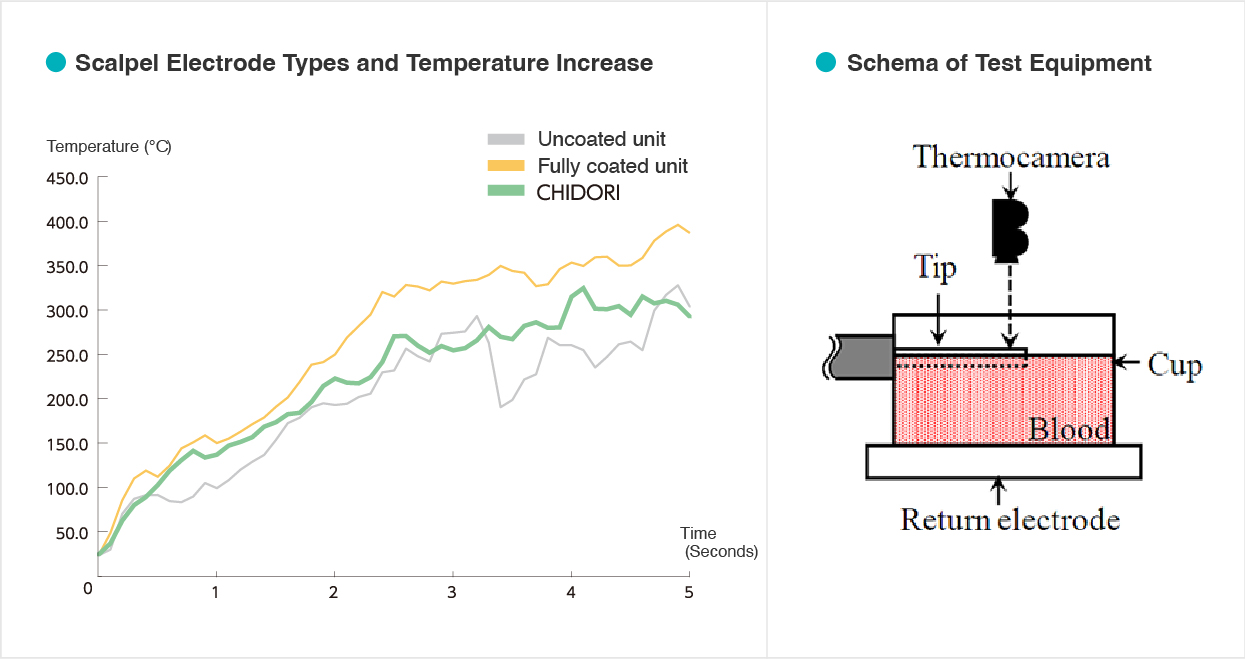

Control of Temperature Increase

In order to measure temperature increase during discharge, the tips of the three scalpel electrodes were inserted in 2mm of porcine blood and discharged for 5 seconds while the upper section of each test unit was exposed to the air. The maximum temperature of the test units’ upper sections were measured using an infrared camera. The tested units were an uncoated scalpel electrode, a fully coated scalpel electrode, and CHIDORI.

The test results were as follows. The fully coated unit reached the highest temperature, at approximately 400℃ after 5 seconds. In comparison, CHIDORI’s temperature increased gradually, similarly to the uncoated unit, remaining under 300℃ after 5 seconds. The uncoated unit’s temperature had a stronger tendency to fluctuate than CHIDORI’s. This can be considered to be due to the effect of carbide peeling after resistance increases with carbide adhesion.

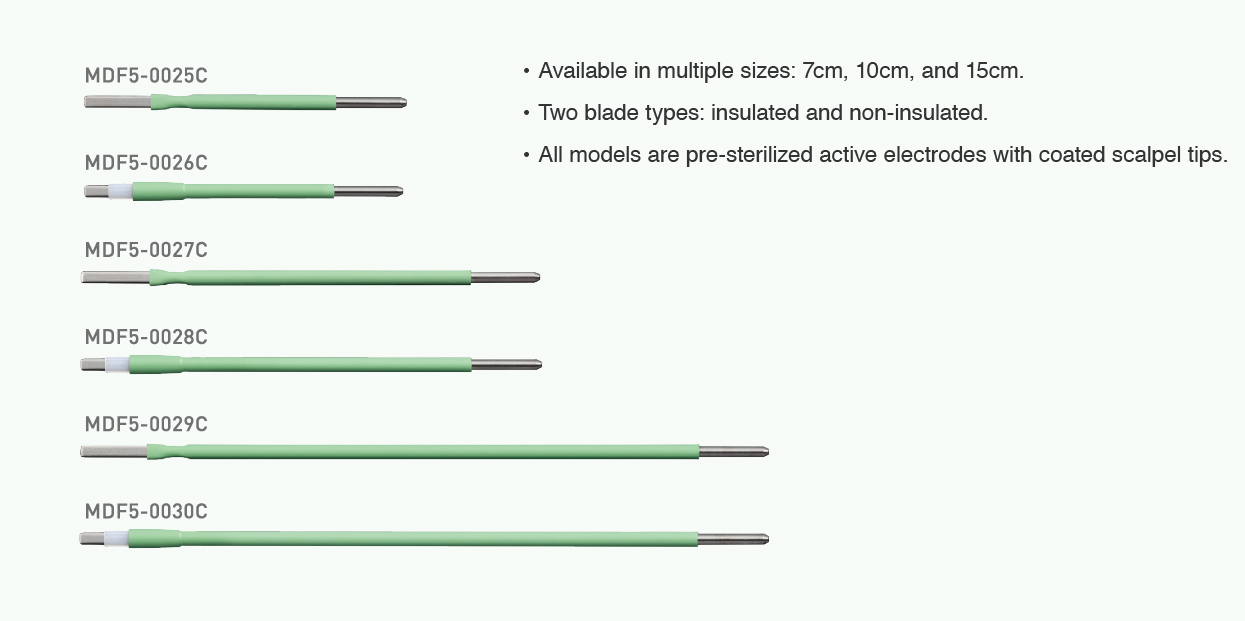

Product Specifications

Brand Name: CHIDORI Disposable Active Electrode

| Product No. | Product Name | Length | Insulated Blade Tip | Packing | JAN Code |

|---|---|---|---|---|---|

| MDF5-0025C | 7cm Coated Blade Electrode | 7cm | – | 10 units per box | 4580618120254 |

| MDF5-0026C | 7cm Coated Blade Electrode, Insulated Type | Yes | 4580618120261 | ||

| MDF5-0027C | 10cm Coated Blade Electrode | 10cm | – | 10 units per box | 4580618120278 |

| MDF5-0028C | 10cm Coated Blade Electrode, Insulated Type | Yes | 4580618120285 | ||

| MDF5-0029C | 15cm Coated Blade Electrode | 15cm | – | 10 units per box | 4580618120292 |

| MDF5-0030C | 15cm Coated Blade Electrode, Insulated Type | Yes | 4580618120308 | ||

| Medical Device Certification No.: 301AGBZX00022000 | |||||